Performance Range

◎ Max.Flow:135m³/h

◎ Max.Head:26m

Application Limits

◎ Maximum liquid temperature +40℃

◎ pH level from 4-10

◎ Maximum liquid density 1.2×10³kg/m³

◎ Power frequency is 50Hz.Norminal voltage is 380VAC for three phase with the range from -10%to+10%

◎ Immersion depth from 0.5m-5m

Certificate

Application Fields

AQ-QG disc cutting sewage submersible pump,implementing Q/SG151 standard.The electric pump is mainly composed of three parts:electric motor,water pump and seal.The motor is located at the upper part of the electric pump.The motor is a two-pole motor.The water pump is located in the lower part of the electric pump.The oil chamber uses a single-end mechanical seal,and the pump chamber uses a single-end mechanical seal Each fixed seal is made of "O"oil-resistant rubber seal for static sealing to ensure the reliability of the electric pump seal. The electric pump rotor shaft is composed of 45 steel and 304 stainless steel friction welding to ensure more reliable mechanical strength of the shaft,which can effectively improve the wear resistance and corrosion resistance of the shaft,and also facilitate the maintenanceand disassembly of the impeller.The water inlet of the electric pump is equipped with a cutting disc,the impeller rotates at a high speed,the cutting disc is fixed on the pump body,and the long fiber cloth,hair and other debris in the water can be chopped during operation,and the gap between the spiral impeller and the cutting disc is small.

Product Usage

◎ Extract domestic sewage

◎ Excluding industrial sewage

◎ Biogas digesters

◎ Sewage treatment

◎ Aquaculture sewage

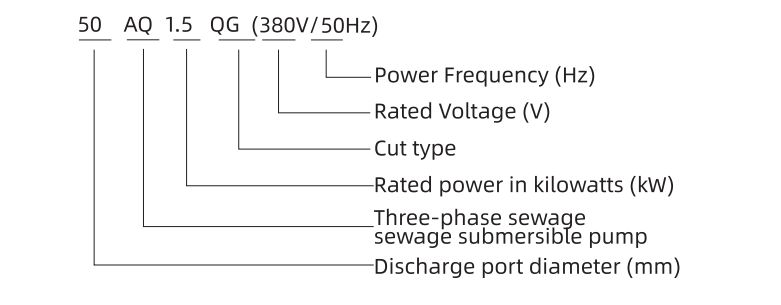

Model Instruction

Performance Range

◎ Max. Flow: 120m³/h

◎ Max. Head: 40m

Application Limits

◎ Maximum liquid temperature+40CpH level from 4-10

◎ Maximum liquid density 1.2×10²kg/m³

◎ Power frequency is 50Hz.Norminal voltage is 380VAC

◎ for three phase with the range from -10% to+10%

◎ Immersion depth from 0.5m-5m.

Certificate

Application Fields

WQ-QG disc cutting sewage sewage submersible pump, implementing Q/SA151 standard. The electric pump is mainly composed of three parts: electricmotor, water pump and seal. The motor is located at the upper part of theelectric pump. The motor is a two-pole motor. The water pump is locatedin the lower part of the electric pump. The oil chamber uses a single-endmechanical seal, and the pump chamber uses a single-end mechanical seal.Each fixed seal is made of "O" oil-resistant rubber seal for static sealing toensure the reliability of the electric pump seal. The electric pump rotor shaft iscomposed of 45 steel and 304 stainless steel friction welding to ensure morereliable mechanical strength of the shaft, which can effectively improve thewear resistance and corrosion resistance of the shaft, and also facilitate themaintenance and disassembly of the impeller. The water inlet of the electricpump is equipped with a cutting disc, the impeller rotates at a high speed, thecutting disc is fixed on the pump body and the long fiber cloth, hair and otherdebris in the water can be chopped during operation, and the gap betweenthe spiralimpeller and the cutting discis small.

Product Usage

◎ Extract domestic sewage

◎ Excluding industrial sewage

◎ Biogas digesters

◎ Sewage treatment

◎ Aquaculture sewage

Model Instruction